Before sailing from the United States to Sweden in 2011, my wife, Mia, and I spent the better part of a year refitting our 1966 Allied Seabreeze yawl Arcturus for ocean sailing. The boat was therefore in tip-top shape when we left Annapolis—save for her old, tired engine. We figured we wouldn’t need it much crossing the Atlantic, as Arcturus carries little fuel, so we left it for another day. Last year, however, the “other day” arrived: our elderly, temperamental Westerbeke had frayed my nerves on one too many occasions, and now it was coming out, to be replaced by a brand-new Beta diesel.

I started by removing all the wiring and hoses. Coolant that had spilled when I removed the heat exchanger created a veritable ice rink in the bilge, making hard work of unbolting the coupling and removing the shift cable from the transmission. Mia and I wrestled the Westerbeke off its mounts by fixing a wood beam across the companionway and hoisting the engine on a block and tackle onto the cabin sole.

While we were at it, we decided to redo the entire engine room and cockpit lockers, from the fuel tank and shaft seal to the battery box and plumbing. So after the engine, out came the fuel tank, followed by the entire contents of the cockpit lockers and lazarette, after which we repainted the bilges so the shiny new engine would look right in its shiny new engine room. The new engine is painted “Kubota Blue,” by the way, not the standard Beta red. I spec’d this on purpose, because I’ve had bad experiences with red engines, and my favorite color is blue. Why not add it to the list of preposterous sailor’s superstitions?

The Beta Arrives

One morning we got the call that the engine had arrived at Mia’s family’s house in Sweden. It literally had been delivered with the post and was sitting on a pallet by the mailbox. We lifted the boxed-up Beta onto a trailer that Mia’s dad borrowed from a neighbor and drove back to the boat, engine in tow. Lars from the boatyard came and removed the prop (and the coupling, which I was sure wasn’t going to budge) and Tommy, the yard manager, helped us lift out the old Westerbeke and lift in the new Beta with his forklift. As fate would have it, Arcturus was moved inside the varmhallen, or indoor shed, the last day before Tommy went on a two-week vacation. Swedes take their vacations very seriously—the entire country practically shuts down for the month of July, so we were just in time.

Our friend Micah soon arrived from Annapolis to help with the actual install. He works professionally refitting boats and has completed over a dozen engine installs, including those on a number of Swans and Hallberg-Rasseys. We paid for his ticket to Sweden in exchange for putting him to work.

The advantage of the “while-we’re-at-it” approach was that when Micah arrived, we had a completely clean engine space to work with. Everything could be designed and installed where it best fit, from the ground up.

The first major challenge was getting the new motor to fit on the old engine beds. One of my biggest mistakes was not measuring the exact width of those beds before ordering the engine. Beta has a custom feet-ordering program, where they’ll build to your exact specs so the new engine can drop right into the old engine’s footprint. However, I hadn’t done those measurements, because I was already back in the States and didn’t have access to the boat, so we had gambled on our beds having standard dimensions. Now I had to deal with the fact that the new Beta’s feet were about a half-inch too wide on either side.

Before Micah arrived, I had come up with the idea of using some stainless steel angle iron to make up the extra width and simultaneously create a more stable base for the feet. Fortunately, I was able to find the one steel foundry that was both open in July and sold what we needed, and they cut two 15in lengths of 10mm thick 304 stainless angles that were about 4 inches on each side. After measuring for the extra cuts and holes we needed to have drilled, we then took them to a small family-run machine shop out in the countryside for the final machining, drilling and tapping.

Getting the engine onto the newly modified beds was straightforward, as we used the same tackle arrangement braced in the companionway that had helped us get the old one out. One advantage of having the stainless steel covering the beds was that it provided a smooth and slippery surface on which to slide the engine fore and aft to get the alignment just right.

By now we’d also cleaned up the old prop shaft and installed a new PSS dripless shaft seal and cutless bearing. We’d also ordered a new shaft coupling, plus a flexible coupling from Beta that fit between the gearbox and the shaft to absorb engine vibration. It took the better part of a day to get the alignment right.

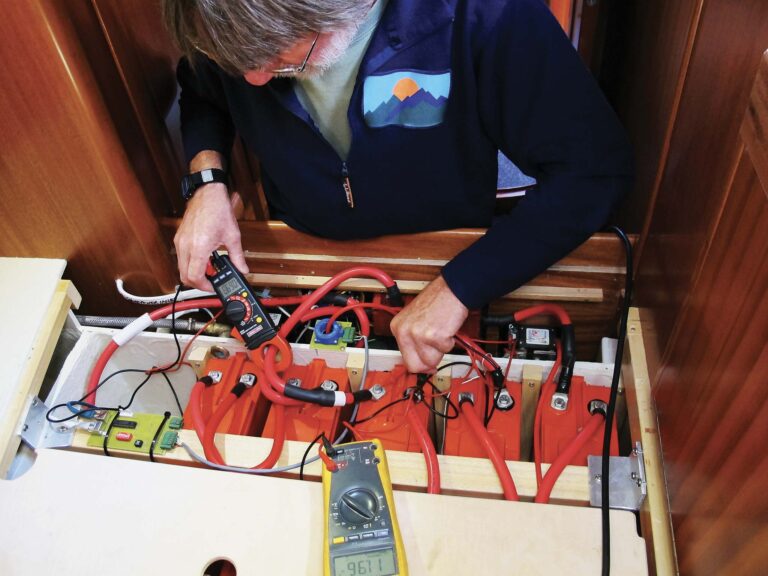

Once the engine block was bolted in place it was time to install the surrounding systems. The fuel tank took priority, as it would dictate where the filters and lines were run. I’d ordered a standard-size plastic tank from Vetus to mount on a shelf we had built on a forward bulkhead in the starboard cockpit locker. A custom tank would have cost almost four times as much. Since the batteries were relocated immediately opposite in the port locker, the weight would balance out. Our new tank’s capacity is 88 liters, or about 22 gallons.

I’d ordered the Beta with the optional solid copper fuel lines, which Micah very neatly snaked around the cockpit locker bulkheads and into the compartment underneath the sink. As he did so, I learned of his affinity for zip ties—all the new hoses, wiring, fuel lines and other odds and ends now resemble train tracks as they snake around the engine room. Very clean and tidy.

One of the benefits of a Beta engine is the handy placement of all regular service points. The impeller, alternator and belt, dipstick, and oil and primary fuel filters are all located on the front of the engine. The bulkhead under the galley on Arcturus has a large opening door, making this area accessible. Micah also installed a new 1in Groco intake strainer underneath the sink near the other service points, utilizing some of the space that resulted from the Beta’s smaller footprint. We mounted the fuel filter next to it for the same reason.

With the engine, fuel and cooling systems installed, we could see the light at the end of the tunnel. Micah’s time was also about up, and he soon returned to Annapolis and his own 1962 Alberg 35, Entropic. I’d be on my own, including for the crucial moment of truth when it came time to fire up the new beast.

Splashing Arcturus

After a weekend off, I returned to work on the boat with renewed vigor, inspired by a visit to the Arctic Fram museum and the knowledge that by the end of the week—some six weeks after the project had begun—our boat would be back in the water. The Campbell Sailer prop, the last piece in the puzzle on order from North by West in British Columbia, finally arrived. Despite my misgivings, it fitted.

Tommy came with his remote-control travel lift, and we walked with him down to the boat ramp. Arcturus happily floated off. I filled the engine with oil, made sure the electrical system was reconnected, turned the key and…the Beta came to life!

Arcturus wasn’t yet a sailboat—we still had to step the mast, using the self-serve hand-cranked crane at the boatyard next door—but she was the most reliable powerboat we’d ever had. The refit work that we’d began way back in 2010 in Annapolis prior to crossing the Atlantic was now officially complete. Arcturus is in better condition than ever; now it’s up to us to sail her further than she’s ever gone before.

Why we downsized

The Beta 16 replaced our larger Westerbeke 30BIII, and the engine downsize was intentional. It saved weight, space and money. Better still, it encourages us to use the boat the way we like—as an auxiliary sailboat.

Even Bernard Moitessier, one of the most purist cruising sailors there ever was, had a small diesel engine, a little 4hp motor that would propel Joshua at 3 or 4 knots in a flat calm and help him get into and out of the dock. On long voyages, he removed the prop to reduce drag.

Partly influenced by Joshua, we took a middle ground: the 16hp Beta is slightly underpowered for Arcturus’s 12,500lb displacement, but still gives us 5 knots in calm water and allows us to maneuver in and out of marinas and tight anchorages. Because the boat is easily driven under sail, in light air we can usually sail faster than we can motor.

We also over-sized the prop, consulting with fellow SAIL writer Nigel Calder to ensure we did it right. “If you don’t need the top end, you will significantly improve engine efficiency by technically oversizing the propeller—i.e., sizing it such that the engine won’t get past, say, 2,400rpm,” Calder said. “A good rule of thumb is to size the prop such that it drops the maximum engine speed by about 400rpm.”

With the oversized “Sailer” we can pull about 2,800rpm (out of 3,600 max), and we cruise at 5.5 knots in a calm at around 2,200rpm, self-limiting the throttle at 2,800rpm so as not to damage the engine.

In the end, we have a proper inboard diesel, but Arcturus is still primarily a sailing boat, which is just the way we like her.

What We Learned

They say you should build your first boat for your enemy, your second boat for your friend and your third boat for yourself. The same applies to installing a new engine.

While the project was ultimately a success, it could have gone much more smoothly had I known what I know now. Here are a few key rules of engine installation I picked up on:

Measure exactly the spacing of the engine beds and where the feet will go so the new motor will drop right in.

Plan out the entire system—from the water plumbing to the fuel, to the electrical—and then try to buy or collect everything you need before work begins. We spent countless hours driving back and forth to the chandlery getting parts.

Remember that tools and fasteners come in all different sizes worldwide. We’d started with the American system, and were now switching to metric in Europe. This posed its own challenges, and we had to re-tool for the project.

One major thing we did “right” was remove everything, and then clean, paint and install from scratch. The engine room looks professional now.

Get friendly with zip ties when running wiring and plumbing to keep everything organized.

All photos by Maria Karlsson