Anyone who has played with electrical gear for any length of time is familiar with the distinctive smell of burned windings. Unfortunately, this smell, wafting out of engine rooms from fried alternators, may soon become familiar to a much wider audience. Why might alternators, generally known for their reliability, become more likely to fail in the next few years?

The answer lies in changing battery technology. Two technologies in particular are rapidly gaining a toehold on boats. First there is Thin Plate Pure Lead (TPPL) technology, which is available in Odyssey batteries; second we have lithium-ion batteries, which are finding their way into the marine world in a number of different guises. What distinguishes these battery types is that they have very high charge-acceptance rates compared to traditional lead-acid batteries.

What does this mean in practical terms? When discharged, a conventional lead-acid battery initially accepts moderately high levels of charging current, but no matter how much charging current is available, this charge-acceptance rate rapidly declines. As a result, charging devices such as alternators and battery chargers typically work hard initially, but within minutes, even seconds, the charging current tapers off and the device is “coasting” at well below its rated output. In contrast, these new batteries can absorb all the charging current thrown at them until almost fully charged, thus driving charging devices to full continuous output for extended periods of time. Most battery chargers can handle this, but most alternators cannot—they overheat and burn out as their diodes and stator windings fail.

The problem is that alternators are inherently inefficient. They are at best less than 60 percent efficient; often they are well below 50 percent. The other 50 percent of the energy supplied to the alternator via its belt is turned into heat. In a typical charging cycle, the alternator starts out cold, then goes to full output at the beginning of the charging cycle and rapidly heats up. Before it gets dangerously hot, however, the charging rate declines and the alternator’s fan drives enough air over and through the unit to stabilize the temperature and keep the alternator from burning up. With these new batteries, the alternator is likely to be pegged at full output, the fan can’t handle the heat load, and the temperature rises until something fails.

One obvious way to avoid this problem is to not use the new batteries, and I’ve had alternator manufacturers suggest they will not warranty their products when mated with them. But this is shortsighted. These new battery technologies are the single most important breakthrough in marine electrical efficiency that we’ve seen in over three decades. They remove the principal roadblock to designing truly effective electrical systems for boats, and we must find a way to fully exploit them.

What we need are alternators that can withstand higher workloads. There are three obvious ways to achieve this:

1. Improve heat dissipation. The simplest way to do this is to use large-frame alternators in place of small-frame alternators. Large-frame units have a substantially greater surface area and as such dissipate heat better. Due to their large size, however, they may not fit in many engine rooms. Another option is liquid cooling, but this drives up cost and has undesirable installation implications.

2. Increase alternator efficiency so that less of the input energy is turned into heat. The technology is available to do this, notably by replacing wound rotors with permanent magnets, but this is expensive and the resulting output is harder to regulate than that of conventional alternators.

3. Limit alternator output to keep temperatures from becoming destructive. This can be done with a temperature sensor that lowers output as the temperature increases, or via an amperage limit on output (effectively de-rating the alternator). Both approaches are possible with many of the external multi-step voltage regulators already on the market, but cannot be implemented with the internal voltage regulators that come with the alternators fitted as standard equipment on most marine engines.

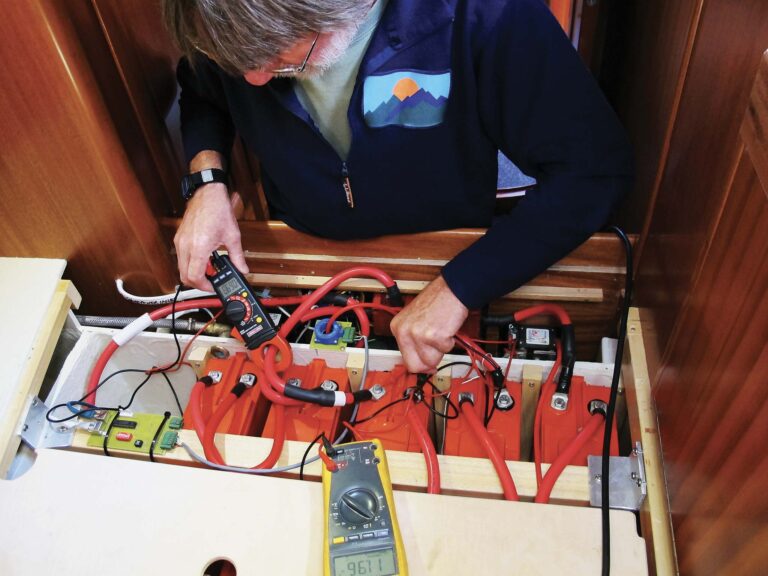

For now, my recommended approach is to use high charge-rate batteries (TPPL or lithium) for the house bank and conventional lead-acid batteries (wet cell, gel cell or AGM) for engine cranking. The alternator that comes with the engine can charge the cranking battery, which is what it is designed to do. On the house side I’d add the most powerful externally regulated large-frame alternator that will fit. Then use the external regulator to limit amperage to no more than 70 percent of the alternator’s rated output (e.g., 140 amps on a 200-amp alternator). If the regulator has a temperature sensor—some do, some don’t—so much the better.

To push a system really hard, the voltage regulator’s current limit should initially be set around 70 percent of rated output. Then fire up the engine and run the alternator at the full regulated output. Use an accurate temperature sensor to measure the temperature on the outside of the stator stack. Once the temperature has stabilized, slowly increase the voltage regulator’s current limit until the temperature rises as high as 240F, but no higher. This test needs to be done with batteries that are sufficiently discharged to keep the alternator running constantly at its maximum regulated output. The alternator temperature should be allowed to stabilize every time the current limit is raised. The engine compartment should also be at its highest likely ambient temperature.

In time, I am sure someone will rise to the challenge and build cost-effective alternators that can run continuously at fullrated output. In the interim, the measures described here should allow you to exploit the new battery technologies without smelling any burned windings.